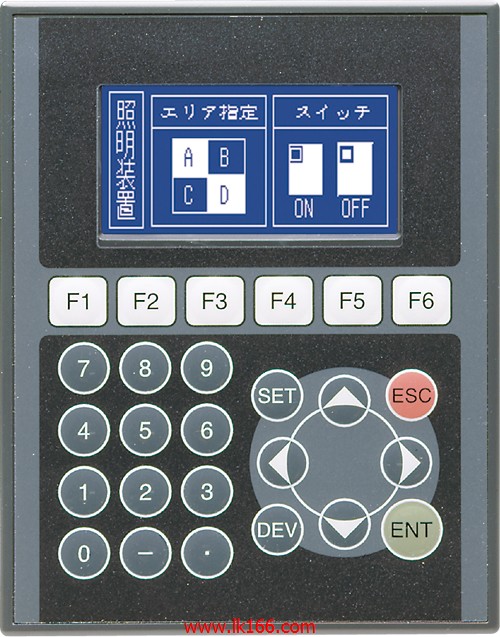

F920GOT-BBD-K MITSUBISHI F920GOT-BBD-K

Memory format: EPROM.

Number of steps:

Can use up to 16000 steps.

Battery support: do not.

Method of writing and deleting: write and use ROM to write, use ultraviolet ray to delete. Can be used as a screw relay terminal. Negative common end use

Series Name: F920GOT with buttons, with a series of effective functional modules F920GOT-BBD-K.

System screeen display language: japanese.

Display: 2.6 inches.

Display color: monochrome (blue / white).

Display device: LCD STN.

Resolution: 128 * 64 F920GOT-BBD-K.

Installation type: panel mounting.

The built-in communication port: RS-422 (1ch) /RS-232C (1ch).

Power supply voltage: DC24V.

The touch screen is the interface between people and machines in the field of information exchange and function contact or interact with each other,

Information exchange, functional contact or mutual influence, the hard contact and soft touch of a person and machine,

This interface includes not only the direct contact point, including long-distance information transmission and control function space F920GOT-BBD-K.

The man-machine interface is the central link in the man-machine system,

Mainly from the safety engineering branch of the safety ergonomics to study and put forward the basis for the solution,

And over safety engineering equipment engineering,

Safety management engineering and safety systems engineering to study the specific solutions and measures of the safety of human computer science MITSUBISHI F920GOT-BBD-K MITSUBISHI F920GOT-BBD-K. Convert connector to screw relay terminal.

According to the location of the connection equipment distribution module. MITSUBISHI inverter series: FR-F840.

Voltage level: three phase 400V.

Power: 75kw MITSUBISHI F920GOT-BBD-K.

SLD converter rated current: 180A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

The motor efficiency is not changed in the previous optimal excitation control,

At the same time, the newly developed advanced optimal excitation control can obtain larger torque at startup.

No need to adjust the parameters (plus deceleration time or torque, etc.), in a short time to speed up to a certain speed,

Can be carried out to maximize the efficiency of energy-saving drive motor.

The automatic tuning function of the loop constant of the motor is not consistent with the constant of the motor, the motor of other manufacturers, and the length of wiring is too long,

Optimum operating characteristic drive motor.

In the state of the sensor can not only drive the high efficiency and energy saving motor and PM motor (MM-EFS), but also ccan drive other companies induction motor and PM motor (permanent magnet synchronous motor) F920GOT-BBD-K.

Other manufacturers of induction motors, can also be automatically tuned to achieve the best excitation control, thus expanding the use of energy saving.