Home

>> Products

>> OMRON

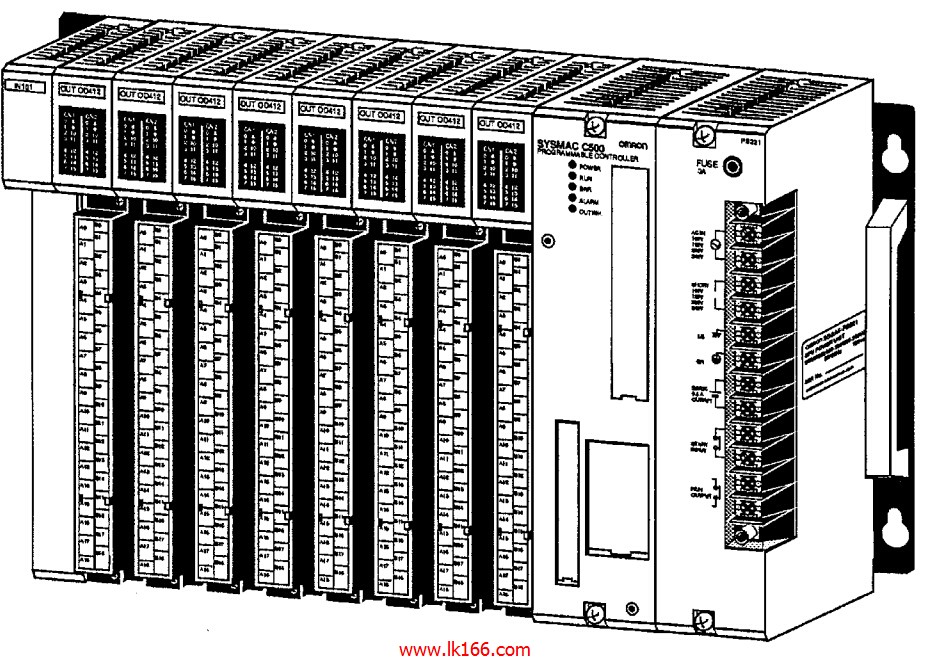

>> CVM1/CV500/C500/C1000 PLC

>> C500 (3G2A5) series PLC

>> C500-DA101 OMRON C500-DA101

C500-DA101 OMRON C500-DA101

Brand:

OMRON

Name: Analog Output Module

Model: C500-DA101

C500-DA Special I/O Unit Analog Output C500-DA101.

Output: 4 pts.

Specification: +1~+5V、0~+10V、4~20mA.

...More relevant models >>>>

Name: Analog Output Module

Model: C500-DA101

C500-DA Special I/O Unit Analog Output C500-DA101.

Output: 4 pts.

Specification: +1~+5V、0~+10V、4~20mA.

C500-ID Special I/O Unit ID Sensor Unit General Purpose C500-IDS21.Model: C500F-CPUA1(3G2C3-CPUA1).

C500F-CP CPU Programmable Controller C500F-CPUA1.I/O Cable (for I/O to Interface Racks) 0.6 m (L) CV500-CN612CV500-VP CPU Bus Unit Personal Computer Unit Main Mem CV500-VP223-E.

4-MB memory; w/floating-point processor OMRON C500-DA101. Supply voltage: 24V DC.

Output capacity: DC5V, 6.5A.The initial configuration of the G language unit in the industry due to the use of G language,

Complex processing procedures do not need to be able to make the ladder diagram C500-DA101

The realization of the first 1 axis simultaneous control of 4 axis simultaneous control in the industry is due to the multi task function,

Can be executed at the same time or the 2 axis simultaneous control of 4 axes, and then can achieve the 4 axis independent control, etc OMRON C500-DA101.

Up to 8 units can be installed CVM1 8 units can be installed 1 units, can control up to 32 axes.

Applicable to ABS encoder by standard,

Applicable to the ABS type (absolute output) encoder, so after the emergency stop, no need to search for the origin, etc..

S curve also according to the standard configuration plus deceleration curve, in addition to the trapezoidal outside,

Also configured to suppress the mechanical vibration of the S shape curve OMRON C500-DA101.

Program login maximum of up to 100

G language can be programmed with the MC support software GModel: C500-CN231.

Cable length: 20 m.

Programming Console Connecting Cable.

For extension and connection of FIT of FIT.

Supply voltage: 100 to 120 or 200 to 240 VAC, 50/60 Hz

Output capacity: DC5V, 6.5AC500-OC I/O Unit Transistor Output 16 pts C500-OC221(3G2A5-OC221).

AC250/DC24V 2A.I/O Cable (for I/O to Interface Racks) 1 m (L) CV500-CN122C500-DA/3G2A5-DA Special I/O Unit Analog Output C500-DA004(3G2A5-DA004).

Output: 2 pts.

Specification: -10~+10V.I/O Cable (for I/O to Interface Racks) 10 m (L) CV500-CN132CV500-CN Cable Bus Connecting Cable Used to join two Hard Disk Units CV500-CN116.Control specifications: voltage output / pulse train output.

Axis of control: 1.

Location data: 200.

Connection with servo motor drive,

The location data is transmitted by PC to carry out high precision positioning.

Can set the number of different types of products and location parameters, and can monitor the operation process online.

Equipment operation is flexible and convenient, can achieve start and pause,

Automatiic and manual mode switching, counting and zero, cylinder pressure time adjustment, etc C500-DA101. .

Screw automatic discharge, feeding, fixed, the machine is automatically completed by one time, without manual assistance.

High speed production beatt, can achieve a single station speed of not less than 1-1 C500-DA101. 5 seconds / piece.

Positioning accuracy is high, the position error is not more than 0.02 mm.

C500F-CP CPU Programmable Controller C500F-CPUA1.I/O Cable (for I/O to Interface Racks) 0.6 m (L) CV500-CN612CV500-VP CPU Bus Unit Personal Computer Unit Main Mem CV500-VP223-E.

4-MB memory; w/floating-point processor OMRON C500-DA101. Supply voltage: 24V DC.

Output capacity: DC5V, 6.5A.The initial configuration of the G language unit in the industry due to the use of G language,

Complex processing procedures do not need to be able to make the ladder diagram C500-DA101

The realization of the first 1 axis simultaneous control of 4 axis simultaneous control in the industry is due to the multi task function,

Can be executed at the same time or the 2 axis simultaneous control of 4 axes, and then can achieve the 4 axis independent control, etc OMRON C500-DA101.

Up to 8 units can be installed CVM1 8 units can be installed 1 units, can control up to 32 axes.

Applicable to ABS encoder by standard,

Applicable to the ABS type (absolute output) encoder, so after the emergency stop, no need to search for the origin, etc..

S curve also according to the standard configuration plus deceleration curve, in addition to the trapezoidal outside,

Also configured to suppress the mechanical vibration of the S shape curve OMRON C500-DA101.

Program login maximum of up to 100

G language can be programmed with the MC support software GModel: C500-CN231.

Cable length: 20 m.

Programming Console Connecting Cable.

For extension and connection of FIT of FIT.

Supply voltage: 100 to 120 or 200 to 240 VAC, 50/60 Hz

Output capacity: DC5V, 6.5AC500-OC I/O Unit Transistor Output 16 pts C500-OC221(3G2A5-OC221).

AC250/DC24V 2A.I/O Cable (for I/O to Interface Racks) 1 m (L) CV500-CN122C500-DA/3G2A5-DA Special I/O Unit Analog Output C500-DA004(3G2A5-DA004).

Output: 2 pts.

Specification: -10~+10V.I/O Cable (for I/O to Interface Racks) 10 m (L) CV500-CN132CV500-CN Cable Bus Connecting Cable Used to join two Hard Disk Units CV500-CN116.Control specifications: voltage output / pulse train output.

Axis of control: 1.

Location data: 200.

Connection with servo motor drive,

The location data is transmitted by PC to carry out high precision positioning.

Can set the number of different types of products and location parameters, and can monitor the operation process online.

Equipment operation is flexible and convenient, can achieve start and pause,

Automatiic and manual mode switching, counting and zero, cylinder pressure time adjustment, etc C500-DA101. .

Screw automatic discharge, feeding, fixed, the machine is automatically completed by one time, without manual assistance.

High speed production beatt, can achieve a single station speed of not less than 1-1 C500-DA101. 5 seconds / piece.

Positioning accuracy is high, the position error is not more than 0.02 mm.

...More relevant models >>>>

Last one: OMRON Analog Output Module C500-DA005(3G2A5-DA005)

Last one: OMRON Analog Output Module C500-DA005(3G2A5-DA005) next one: OMRON Analog Output Module C500-DA103

next one: OMRON Analog Output Module C500-DA103

Related download