Brand sort

MITSUBISHI FR-LU08

Brand:

MITSUBISHI

Country: JAPAN

Name: LCD panel

Model: FR-LU08

Market price: U.S.$ 247.46

(The following are the market open price not sales price!)

(The following are the market open price not sales price!)

MITSUBISHI FR-LU08

Remote I/O controller, optical fiber.

How to choose MITSUBISHI PLC.

MITSUBISHI PLC options include the choice of MITSUBISHI PLC models, capacity, I/O module, power, etc..

MITSUBISHI PLC distribution I/O points and design MITSUBISHI PLC peripheral hardware circuit

Draw the I/O point of the PLC and the input / output device connection diagram or the corresponding table,

This part also can be carried out in second steps FR-LU08

Design PLC peripheral hardware circuit.

Draw the electrical wiring diagram of the other parts of the system,

Including the main circuit and the control circuit does not enter the PLC, etc..

The electrical schematic diagram of the system composed of I/O PLC connection diagram and PLC peripheral electrical circuit diagram FR-LU08.

So far the system''s hardware electrical circuit has been determined. Input type: DC input, positive public end / negative public end.

Input points: 32 points.

Enter the response time: 0.2ms the following.

Rated input voltage / current: DC24V/5mA.

External connection: 1 wire.

According to the external connection mode and the external equipment input and output specifications,

Choose from a rich product lineup FR-LU08.

Finger protection through the upper part of the terminal,

The human body will not be exposed to live parts,

Therefore, the terminal station type remote I/O module can be directly mounted to the machine tool. PCI bus /PCI-X bus.

Support Japanese, English OS.

Multimode fiber optic cable.

Dual loop controller network (control station / common station).

With external power supply function.

I/O control in the first class of open field network module.

CC-Link based on reliable field bus technology,

Able to transmit large number of bits data (such as ON/OFF information) and word data (such as analog information).

Consistency of CC-Link to maintain loop transmission,

And the cycle of transmission and information (instantaneous transmission) communication separately, so as to ensure the timeliness of.

Even if the information reaches saturation, it will not affect the link scan time.

Make the mixed data environment intelligent, to achieve a new manufacturing system IE CC-Link field network module.

Using Ethernet cables and connectors available on the market to reduce costs.

High speed communication capable of communicating with 1Gbps.

Improve the communication response, significantly shorten the cycle time.

Improve the performance of cycle data update. Reduces the transmission delay time and the application of the synchronization waiting time.

Data can be read or written to other station programmable controller.

Status of IE CC-Link field network can be confirmed by Works2 GX.

Can be in the Works2 GX up and down the abnormal position, the cause of the exception, the event record,

So it can reduce the time of abnormal to resume normal operation.

MELSECNET/H network module capable of composing large scale flexible network system.

The MELSECNET/H network system includes the PLC network of the control station and the communication between the stations and the remote I/O network in the remote station remote I/O station.

Optical fiber loop system...... High speed communication off 10Mbps/25Mbps is realized FR-LU08.

The distance between stations, the length of the total cable length, strong anti-interference .

Coaxial bus system...... Using low cost coaxial cable, the network construction cost is lower than that of the optical fiber loop network.

Twisted pair buus system FR-LU08. ..... Combined with high performance price ratio network module and twisted pair cable,

The construction cost of network system is very low.

FR-LU08 Operation manual / Instructions / Catalog download link: /searchDownload.html?Search=FR-LU08&select=5

How to choose MITSUBISHI PLC.

MITSUBISHI PLC options include the choice of MITSUBISHI PLC models, capacity, I/O module, power, etc..

MITSUBISHI PLC distribution I/O points and design MITSUBISHI PLC peripheral hardware circuit

Draw the I/O point of the PLC and the input / output device connection diagram or the corresponding table,

This part also can be carried out in second steps FR-LU08

Design PLC peripheral hardware circuit.

Draw the electrical wiring diagram of the other parts of the system,

Including the main circuit and the control circuit does not enter the PLC, etc..

The electrical schematic diagram of the system composed of I/O PLC connection diagram and PLC peripheral electrical circuit diagram FR-LU08.

So far the system''s hardware electrical circuit has been determined. Input type: DC input, positive public end / negative public end.

Input points: 32 points.

Enter the response time: 0.2ms the following.

Rated input voltage / current: DC24V/5mA.

External connection: 1 wire.

According to the external connection mode and the external equipment input and output specifications,

Choose from a rich product lineup FR-LU08.

Finger protection through the upper part of the terminal,

The human body will not be exposed to live parts,

Therefore, the terminal station type remote I/O module can be directly mounted to the machine tool. PCI bus /PCI-X bus.

Support Japanese, English OS.

Multimode fiber optic cable.

Dual loop controller network (control station / common station).

With external power supply function.

I/O control in the first class of open field network module.

CC-Link based on reliable field bus technology,

Able to transmit large number of bits data (such as ON/OFF information) and word data (such as analog information).

Consistency of CC-Link to maintain loop transmission,

And the cycle of transmission and information (instantaneous transmission) communication separately, so as to ensure the timeliness of.

Even if the information reaches saturation, it will not affect the link scan time.

Make the mixed data environment intelligent, to achieve a new manufacturing system IE CC-Link field network module.

Using Ethernet cables and connectors available on the market to reduce costs.

High speed communication capable of communicating with 1Gbps.

Improve the communication response, significantly shorten the cycle time.

Improve the performance of cycle data update. Reduces the transmission delay time and the application of the synchronization waiting time.

Data can be read or written to other station programmable controller.

Status of IE CC-Link field network can be confirmed by Works2 GX.

Can be in the Works2 GX up and down the abnormal position, the cause of the exception, the event record,

So it can reduce the time of abnormal to resume normal operation.

MELSECNET/H network module capable of composing large scale flexible network system.

The MELSECNET/H network system includes the PLC network of the control station and the communication between the stations and the remote I/O network in the remote station remote I/O station.

Optical fiber loop system...... High speed communication off 10Mbps/25Mbps is realized FR-LU08.

The distance between stations, the length of the total cable length, strong anti-interference .

Coaxial bus system...... Using low cost coaxial cable, the network construction cost is lower than that of the optical fiber loop network.

Twisted pair buus system FR-LU08. ..... Combined with high performance price ratio network module and twisted pair cable,

The construction cost of network system is very low.

FR-LU08 Operation manual / Instructions / Catalog download link: /searchDownload.html?Search=FR-LU08&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

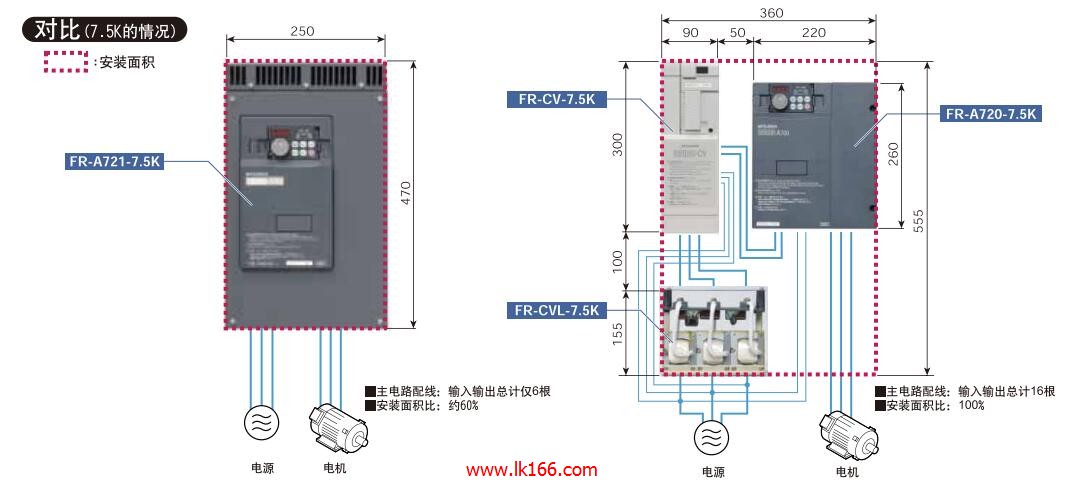

3 phase 400V converter

FR-D740-5.5K-CHT

MITSUBISHI inverter FR-D740 series.

Volt

MITSUBISHI

Common DC bus converter

FR-CV-H22K

Power: 22kw.

Voltage: 400V.

There are 10

MITSUBISHI

3 phase 200V converter

FR-A720-11K

MITSUBISHI inverter FR-A720 series.

Volt

MITSUBISHI

Common DC bus converter

FR-CV-37K

Power: 37kw.

Voltage: 200V.

There are 10

Related download

next one:

next one:  Last one:

Last one: